The Problem

These comparative images show an electric motor in normal light(right) and the same motor via infrared imaging (left) which identifies a clear overheating condition. Further investigation revealed that the overheating was caused by ’dirty’ electricity… a common cause of equipment failure.

Image courtesy of IRINFO Group (www.irinfo.org)

Most of us who own a car have experienced getting a “bad” tank of gas. The engine’s hard to start, it may run rough, cough or sputter and in the worse case, quit altogether. While most cars will tolerate some “bad” gas, with little impact other than lowered gas mileage, too much requires a trip to your mechanic, and an overload means a new engine. Electricity and all the electrical devices that on it are (in this context) really not all that different than the gas you use for fuel and your car’s engine. The problem is, electricity is almost always “bad” or “dirty” (to greater or lesser degrees), and knowing that, the manufacturers of electrical devices design in a range of tolerance to allow their device to keep working… But, like your car’s engine, it may run “rough, cough or sputter” while, other than using more electricity, it keeps on going. And if the electricity is too ‘dirty’? Just like your car, it means breakdown, repair and/or replacement.

The Complication

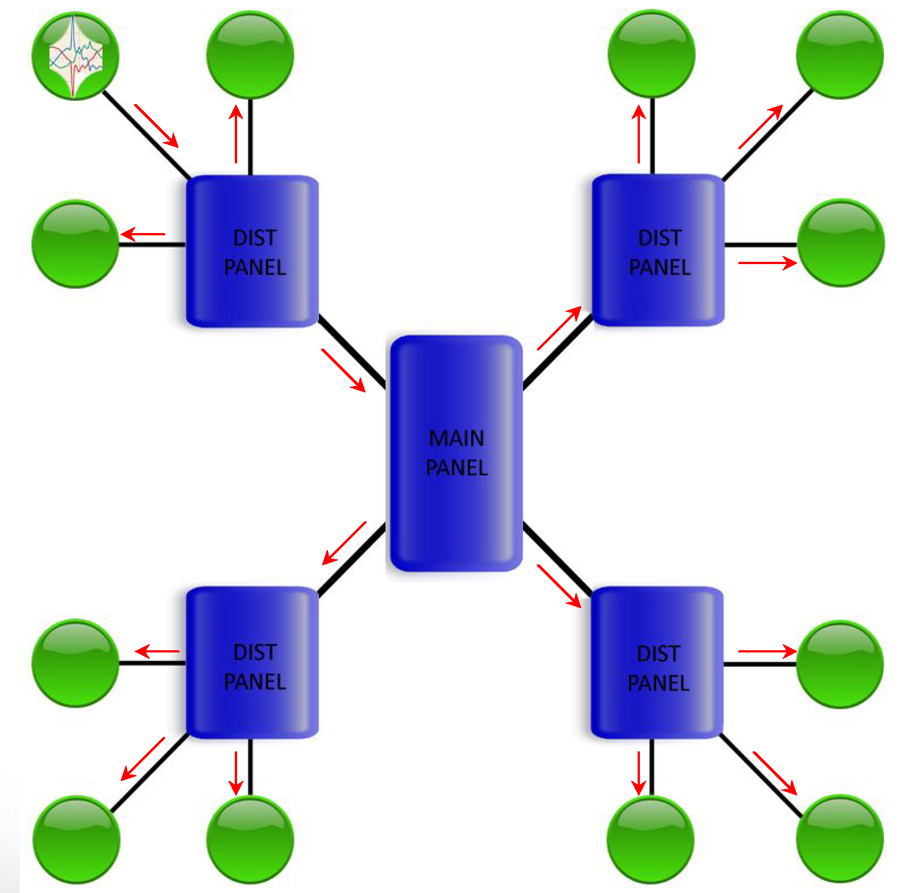

Your electricity operates on a system… it’s all interconnected. To further complicate the issue, your system is only one of many that make up the electrical grid, which is just a larger system… again, all interconnected. What that means, is if your neighbor has an electrical problem, there is a significant probability that it will travel through the grid, and be your problem too.

We describe dirty electricity as being ’viral’. Like a virus in your body that effects your overall health, ’dirt’ in electrical system impacts everything that’s connected. The image to the right illustrates the travel of one of these ’dirt’ occurrences, caused by an HVAC motor powering on, through the electrical system of a normal facility

The Dirt

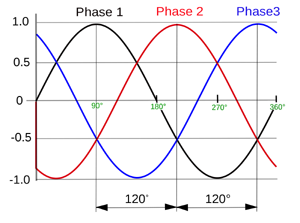

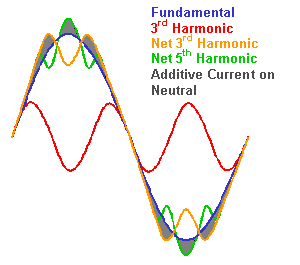

Our entire electrical power system has been developed with sine waves in mind. The ideal 3 Phase sine wave pattern is sinusoidal such as the example shown to the left. Note the clean, smooth wave pattern of each Phase, with the wave topping at 90°, bottoming at 270° and returning to its base level (“0”) at 360°. Operating on electricity with this pattern of delivery, our electrical devices would run in ‘steady-state’… smoothly and at ideal temperatures and consumption levels…

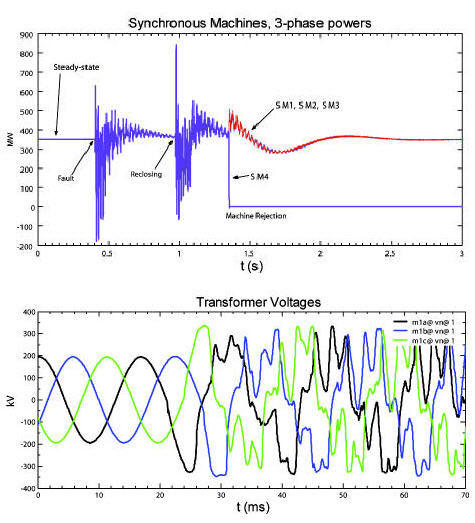

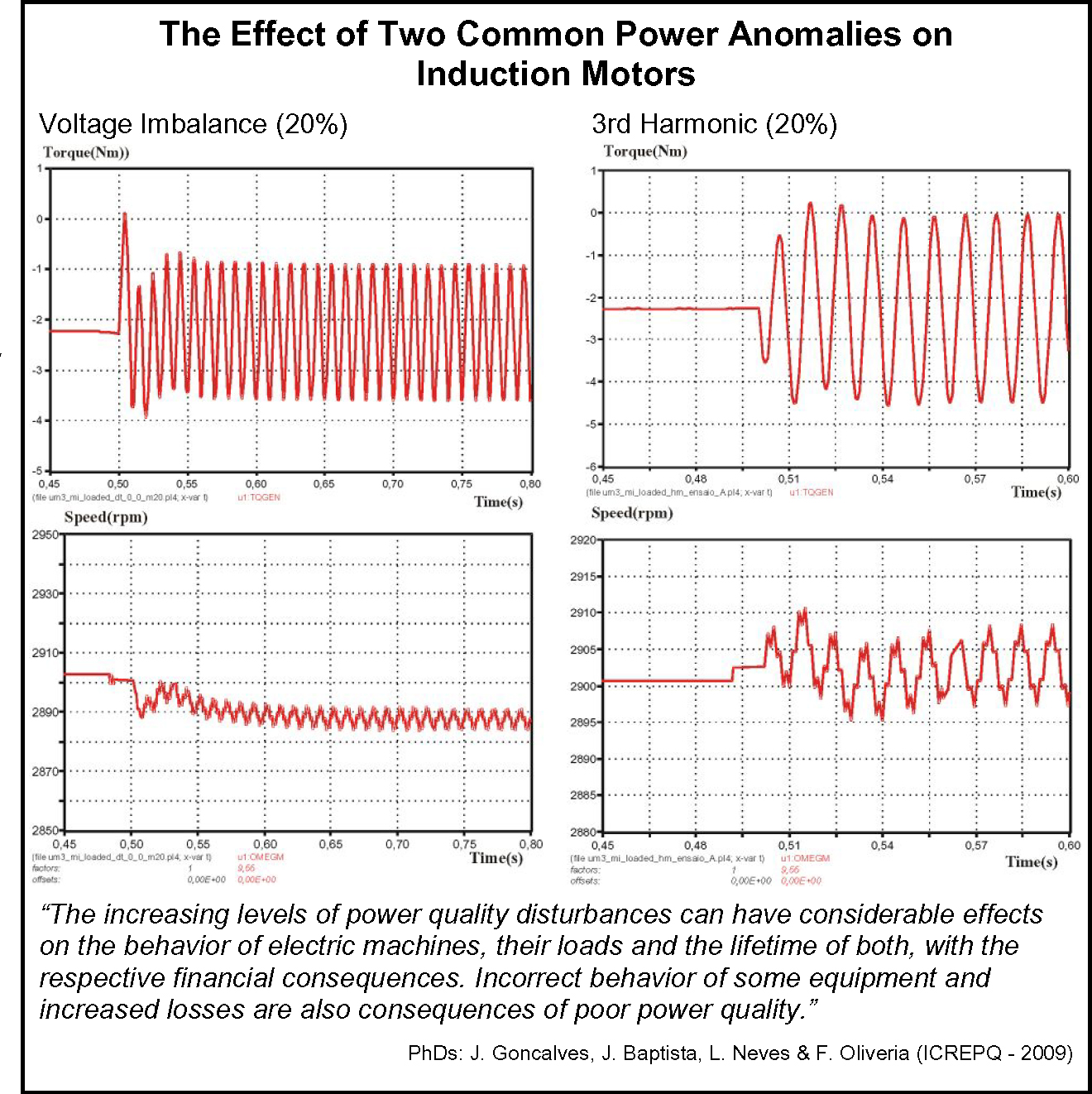

“Dirt” (properly called power anomalies) is constantly & continually present polluting the wave pattern. Simply put, the ‘dirt’ in our electrical systems are the result of Surges, Transients and Total Harmonic Distortion (THD). These ‘events’ impact the ideal wave pattern with distinct and measurable results. The illustration (top right) shows an ‘event’ delivered to a 3 Phase powered machine from steady-state to rejection (machine off-line = downtime). The illustration on the lower right, shows an ’event’ affecting a transformer and the impact on the sine-wave pattern.

In some literature, surges and transients are considered interchangeable, but we like to define a Surge as being comparatively slow, prolonged, and with high total energy while a Transient is very fast, but with low total energy. So, a Surge can be caused by a lightning strike or transformer issue somewhere in the “grid” (generally an external problem), while a Transient can be caused by inductive kickback (an electric motor switching on, for example), or electro-static discharge and so on, which usually have an internal source.

THD’s are often the ’dirt’ caused by our electronic age. Fact is, a significant percentage of electronics (computers, printers, photo-copiers, PLC’s, circuit boards, etc.) operate on DC current. That requires an AC-DC inverter (that blackbox between the electrical plug and your laptop for example) in order to operate. Even if you don’t see them, those inverters are EVERYWHERE. And each of those inverters (amongst other sources) create THD, and THD is major cause of electronic failure! In other words, electronics are their own worst enemy. In another example, the experts consider VFD’s (Variable Frequency Drives) a major source of THD, which causes most of the VFD failure! Make no mistake, while electronics are susceptible to damaging THD, so are motors, transformers and many other parts of your facility.

The Impact

The issues associated with “dirty” power are many, varied & include:

While this list could be much longer, we can summarize it by saying that ‘dirty’ electricity costs your company by paying for electricity you actually don’t use, in downtime, repair/maintenance overheads, production issues and on many other different levels… And when costs go up, profits go down!

While there is no one single answer to all of the sources and issues caused by ‘dirty’ electricity, there is a remedy which can make a significant step toward that goal: Sta bl-Power!

bl-Power!